Cooling Systems in the Wine Industry – A Breakdown

Guest Blogger: John Hamlin

Humidity and temperature are the main parameters being controlled in the storage and aging of wine. Temperature affects the rate of chemical reaction in a wine, wherein the reaction rate increases as the temperature increases. In addition, temperature plays a significant role in the volume of air inside the bottle. Humidity also has an effect on keeping the corks in perfect condition. Excess moisture in any storage unit is an undesirable variable in a wine cellar, because it may lead to mold or fungal contamination. Simultaneously, a dry environment can cause corks to shrink and lead to wine oxidation. A good cooling system will significantly impact the quality of your stored wines.

Wine cooling systems, or chillers, are a key component for the proper storage and aging of wine. They provide solutions for controlling the optimum storage parameters, including temperature and humidity.

Operating Principles of Chillers

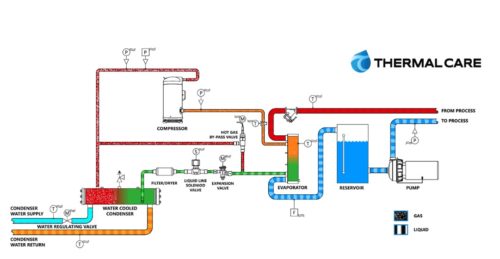

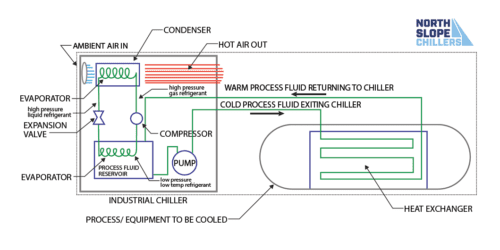

With the wide variety of chillers available, the majority of them work on the same principle of providing a cooling effect. The refrigerant or coolant is an essential part of the whole process in maintaining an efficient cycle. The four fundamental components for chillers are the evaporator, compressor, condenser, and expansion valve. Below is a short description of how these components work together to provide an efficient cooling effect.

The operating principle of chillers may be simply described using the most straightforward refrigeration cycle. Wherein the process will start with a low-pressure refrigerant entering the evaporator. In the evaporator, heat will be absorbed by the refrigerant, which will cause it to boil and change phase into low-pressure vapor. The low-pressure vapor will be converted into high-pressure vapor by the compressor, leading it to the condenser. In the condenser, heat will be rejected from the refrigerant, transforming this into a high-pressure liquid. This liquid will travel to the expansion valve, which controls the refrigerant flow rate to the evaporator.

Types of Chillers used in the Wine Industry

There are three major types of chillers designed for wine storage: self-contained, split, and ducted cooling systems.

Self-contained cooling system. The components in these systems are compacted into one single unit. The condenser and evaporator are assembled inside the equipment, making it easy to install in a wine cellar. With its small build, this cooling system typically has low cooling capacities.

Split cooling systems. Split cooling systems have a remote condenser with only the evaporator mounted in the cellar. These components are connected by insulated lines. This chiller’s main advantage is the elimination of excessive noise and vibration inside that is caused by the condenser and the compressor. This system represents a wide range of cooling capacities s – both low to high loads.

Ducted cooling systems. The main cooling unit assembly of this cooling system is installed remotely from the cellar. The cool air is delivered to the room with the help of the ducting systems. These types are typically installed in wine cellars that have an enormous space.

Choosing the Best Cooling System for your Wine Cellar

Chillers are a must-have in wine cellars in order to allow your prized collection age to perfection. Benefits of installing a wine cooling unit include:

- Maintaining long term storage temperature of approximately 55 °F

- Cooling wine cellars without removing valuable humidity

- Preventing premature aging and oxidation of fine wines

Operating efficiently, quietly, and reliably over time If you’ve invested in fine wine, choosing the correct system involves many variables that must be addressed early on in your project. Let our seasoned experts help you select a cooling system that fits your needs and budget and allows your fine wine to age gracefully.